Case Study

Demo Case Study

Created by

Demo Case Author

,

2025

All of the materials we wear originate from nature’s resources. Linear practices take finite virgin resources from nature as if they were an unlimited supply, clearing land to meet the ever-growing demand of natural materials such as cotton, viscose, wool, rubber, leather hides, etc. The fashion industry is projected to use 35% more land for fibre production by 2030[1], and linear practices waste these precious resources. Of the total fibre input used for clothing, 87% is landfilled or incinerated, representing a lost opportunity of more than US$100 billion annually[2].

As designers, you must find alternative materials that can transition away from linear models that rely on virgin resources, to circular lower-impact solutions. Demo

In this case study we explore how

an alternative biomaterial that does not rely on virgin resources, instead using waste from other industries. As designers, choosing such innovative materials will enable you to implement circular solutions while reducing the environmental impact of your product.

Just like cotton, linen, silk and wool, biomaterials (also called biobased materials), come from plants, trees, or animals — anything from nature. The differences between conventional natural materials like cotton and new alternative biomaterials are how they are farmed and processed. Biomaterials frequently incorporate waste inputs and employ processes that can be inherently more efficient in terms of water, chemicals, and energy usage. [3]

Image credit: Peelshere

Peelsphere® is a material innovation company engineering the biological waste generated from the food industries into a biomaterial for the fashion industry and beyond. Whilst studying in Berlin, textile designer Youyang Song saw the biological waste from fruit harvesting and how it was used in the fields as fertiliser and natural gas production. Through the lens of a textile designer, she saw the opportunity of turning such waste into new textiles. Peelsphere was initiated in 2018 as part of a school project before formally becoming a business, currently located in Berlin, Germany and Shenzhen, China. Peelsphere illustrates how there are opportunities for designers to collaborate with other industries to capture their waste and see them as resources for their creative ideas.

How does it work?

The mono-material composition and digital takeback programme are the two crucial elements that enable easy recyclability in the Circular Series.

All the styles of the Circular Series are using a single material – nylon-6. Econyl®, a regenerated high performance nylon-6 yarn recycled from discarded fishing nets and other waste materials, is used as main fabric, while virgin nylon-6 is used for the filling and trims. The recycling process is therefore simplified. Fibres can be recovered without losing their original characteristics of quality, and used infinitely for new products from the Circular Series.

Their customers also play an important part in Napapijri’s mission. The potential of the recyclable materials would be wasted without the two-year takeback programme. After the purchase is made, customers are encouraged to register their Circular Series items for the programme and return them to the company after at least two years. The material of these pre-loved pieces can then be used to produce new yarn for a new item in the next fashion cycle.

Napapijri is closing the loop of singular fashion by giving consumers an alternative to dumping outdated garments in the landfill.

Image credit: Peelshere

What are the opportunities to scale?

The process is designed to be scalable due to the modular nature of the processing technology. After multiple iterations and updates of materials, they are gradually advancing the construction of large-scale production.

In addition to their own lab testing, Peelsphere collaborates with external research institutes to test for physical and chemical properties, durability, flexibility, and biodegradability.

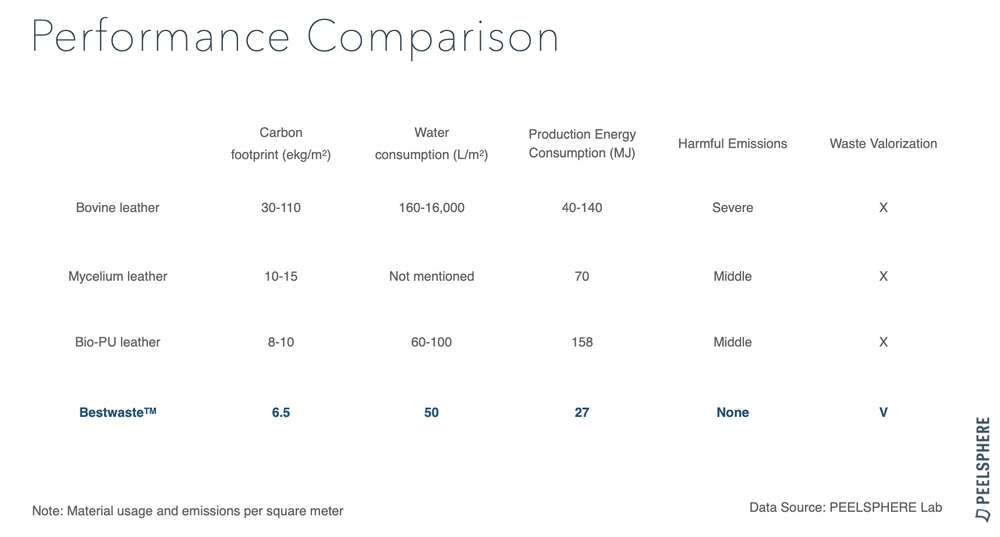

When testing for performance comparison against other similar materials (animal leather, mycelium, and Bio-PU), their carbon footprint, water and energy emissions were significantly lower.

Image credit: Peelshere

Image credit: Peelshere

Choosing a manufacturer to partner with is critical, as they should align with your core values. For Peelsphere®, it is critical to work with suppliers who are able to integrate materials into existing production lines with minimal adjustments. To guarantee a consistent supply, they enter long-term agreements with suppliers. These agreements provide stability for both parties and allow for better forecasting and planning. Equally important to the partnership are their sustainability practices, willingness to innovate, and technological capabilities.

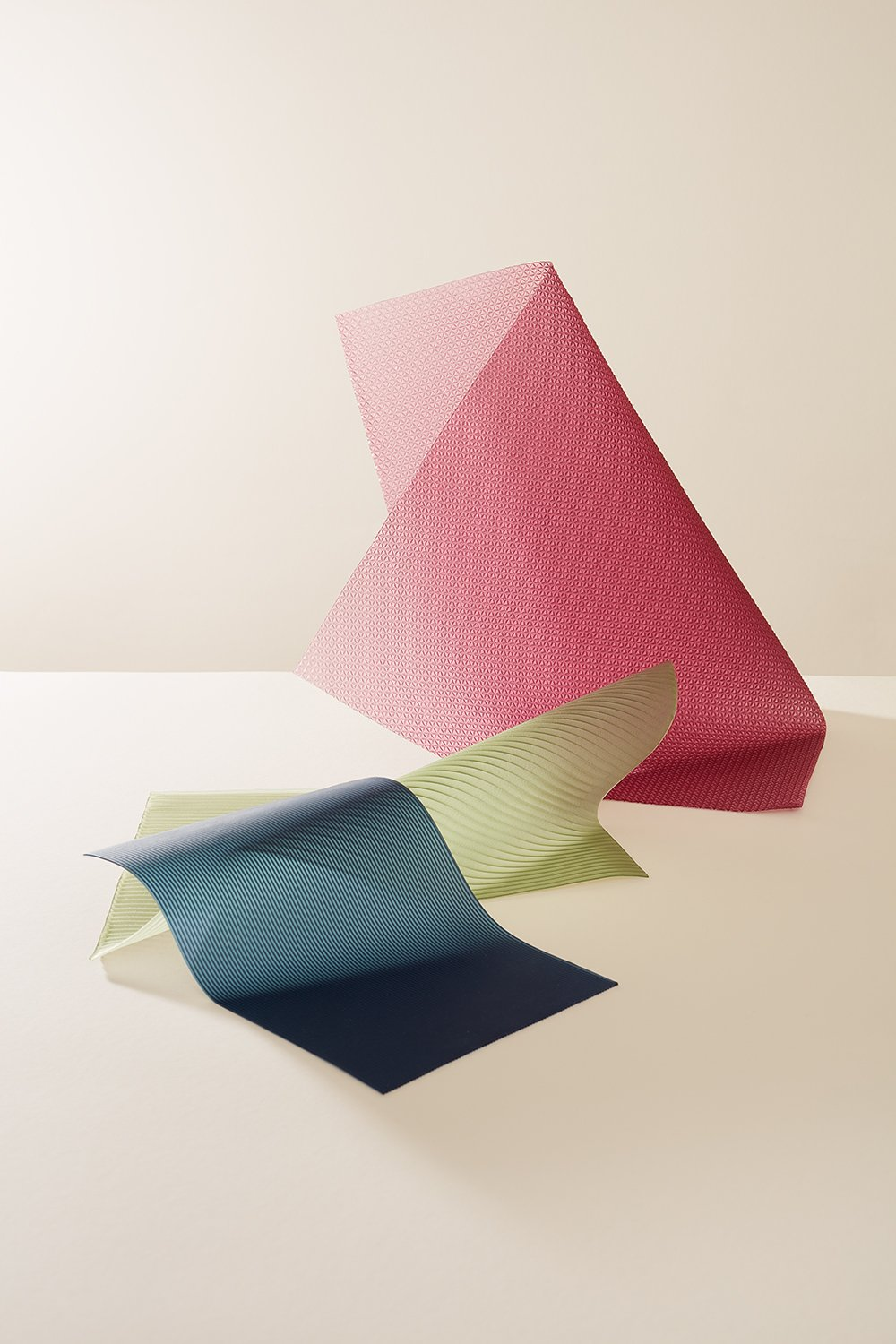

The exciting part of creating new materials is the diversification of end products. This means alternatives not only for the fashion industry, but also for home decor, automobiles, and space installations.

Image credit: Milan Design Week 2023’s spatial installation featured Peelsphere material

Image credit: Peelsphere® buttons

Image credit: Peelsphere® materials

What are the industry challenges?

To reduce our demand on the environment and virgin resources, we urgently need alternative low impact materials. Brands and designers are increasingly interested in biomaterials for their sustainability credentials, but often require detailed information about their performance, care, and application methods, compared with traditional materials. Offering alternative materials is a challenge since scaling to market demands, reaching industry testing standards, and meeting brand and designers’ expectations will NOT be the same as with traditional virgin resources.

Peelsphere® faces challenges achieving consistent quality and performance across batches due to the natural variability in food waste. Also, navigating the complex regulatory landscape for new, biobased materials presents compliance challenges. To maintain a competitive edge, they have patents registered and keep certain proprietary aspects of their technology as trade secrets.

The future for biomaterials

Peelsphere® won the Kering K-Generation Award in 2021 for Innovation in Sustainability. The award facilitated valuable networking, attracting media attention, potential investors, and new business partners, opening doors to exclusive industry events focused on sustainability.

The prize fund (€100,000) fueled research and development, allowing them to scale operations and refine their products. They now have the capacity to produce several thousand square metres of material annually, with plans to increase this as demand grows.

This increased recognition led to strategic partnerships with leading names in fashion, who were keen to incorporate their sustainable materials into their product lines. Awards can provide significant visibility and credibility, offering future collaboration opportunities for sustainable fashion designers.Peelsphere® won the Kering K-Generation Award in 2021 for Innovation in Sustainability. The award facilitated valuable networking, attracting media attention, potential investors, and new business partners, opening doors to exclusive industry events focused on sustainability.

The prize fund (€100,000) fueled research and development, allowing them to scale operations and refine their products. They now have the capacity to produce several thousand square metres of material annually, with plans to increase this as demand grows.

This increased recognition led to strategic partnerships with leading names in fashion, who were keen to incorporate their sustainable materials into their product lines. Awards can provide significant visibility and credibility, offering future collaboration opportunities for sustainable fashion designers.

Image credit: Peelshere

Biomaterials are set to expand significantly in other areas beyond fashion. This includes sustainable packaging, disposable goods, and even high-tech applications like biodegradable electronics and medical implants, facilitating even more competitiveness across other industry sectors.

To transition to a circular fashion system, designers need to fully engage with the material’s unique properties. To understand the processing and application possibilities of biomaterials, work closely together with the suppliers to enable the entire lifecycle.

Learn more

Find out more about Peelsphere® and other materials that will help you source with low impact:

Explore Peelsphere®

Explore Redress Acedemy

Circular fashion course: fibre choices and sustainability

Sustainable material directory

About the Contributor

Image credit: PEELSPHERE® Founder, Youyang Song

Youyang Song is the founder of PEELSPHERE®, a sustainable new materials researcher, and designer.

She is committed to the research and design of innovative biodegradable materials, the development of materials production technologies, and design of the related products.

Her invention of the biodegradable material PEELSPHERE® has been supported by the EU and German governments with programmes and awards such as the Re-FREAM project (EU project number 82564), German Sustainability Award, 2019 Ein & Zwanzig global Talented Designers Award, 2021 Oxford All-Innovate Award, German MATERIALICA Design + Technology Award, German Green Design Award, Kering K-Generation Award, and more.

PEELSPHERE® was selected as a material showing the most potential in 2021. In addition, founder Youyang Song has been selected as one of the most promising designers and as a Green Women Power 100 in 2021.

She has been invited to give courses and lectures at the Central Academy of Arts, Shanghai University of Science and Technology, Ars Electronica BioLab, European Institute of Design in Madrid, and Bio Design Lab at Karlsruhe University of Arts and Design. In addition, she has participated in many design weeks worldwide, such as Milan Design Week, Dutch Design Week, Design Impact Conference, etc.